A game changer

– based on the latest nano technology.

Patented advanced optical coating boasts the following advantages:

- Advanced quality and performance

- Moisture and heat resistance

- Optimized optical performance

- Tests shows a 97% absorption of sunlight

- Environmental friendly production process with no emissions

- Developed using proven coating techniques

- Scalable, investment and cost efficient production

- Short lead time to full scale production

- Flexible processing of materials, molding, bending and coloring

- Architectural flexibility

- Tailoring options

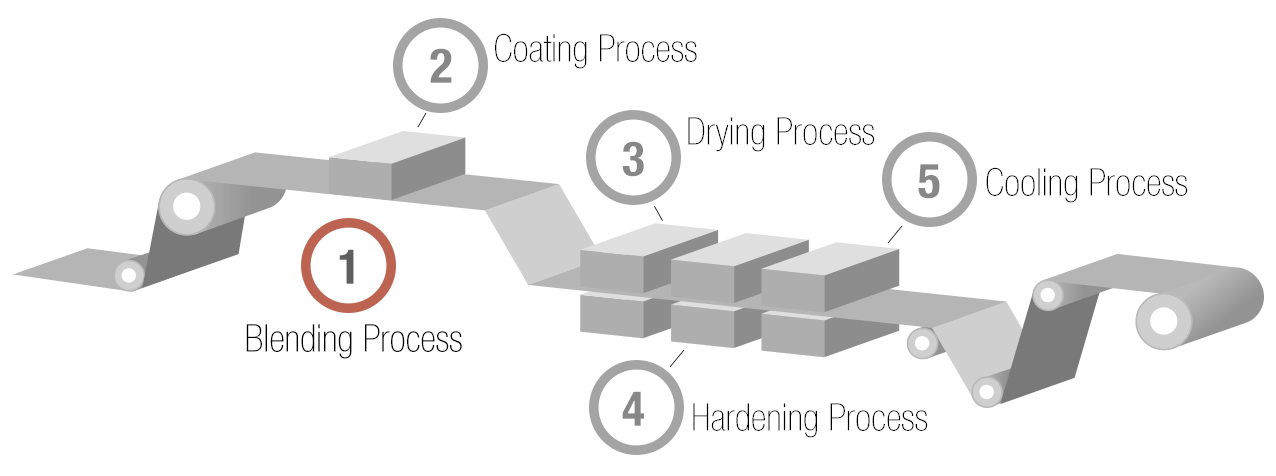

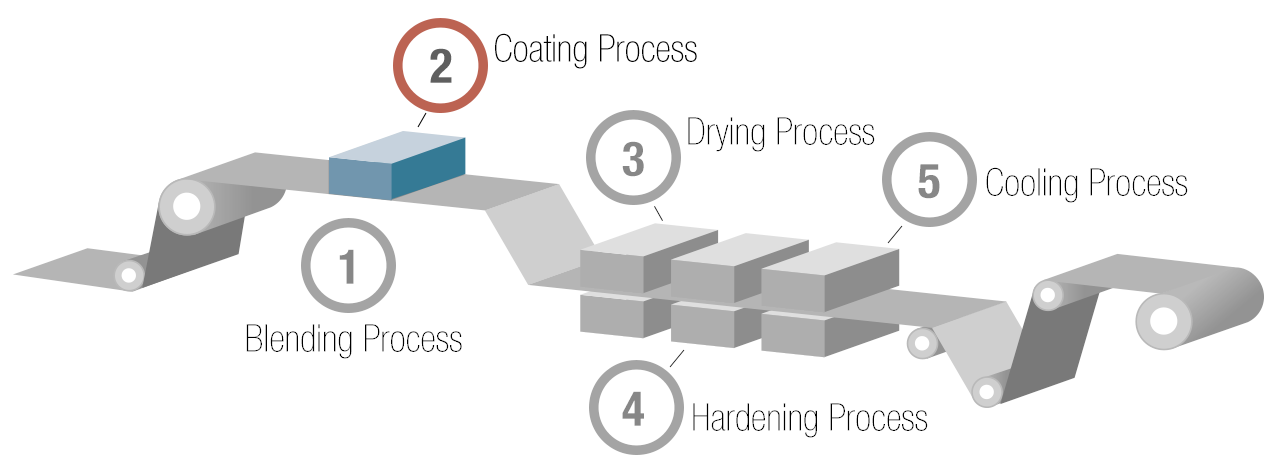

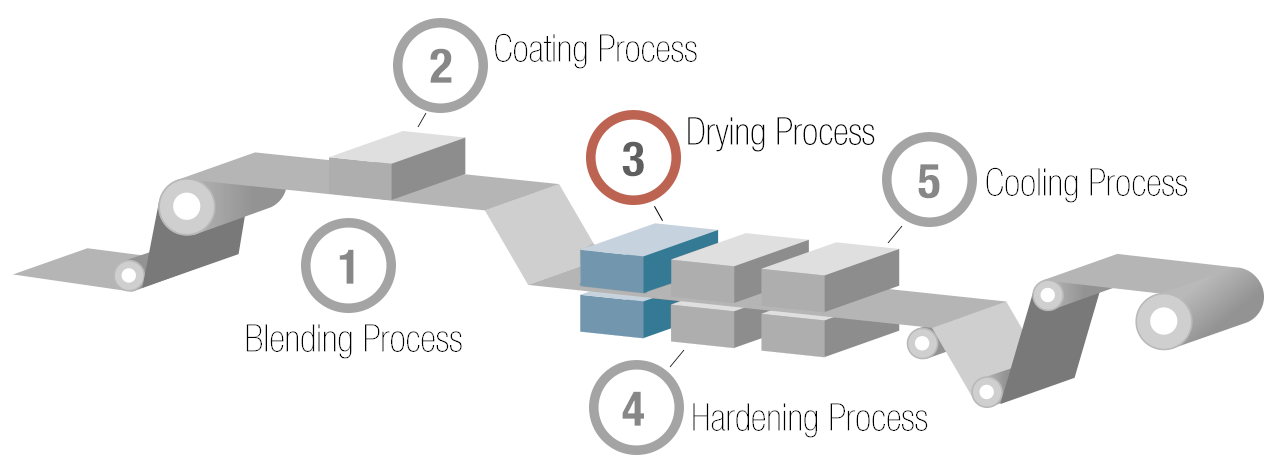

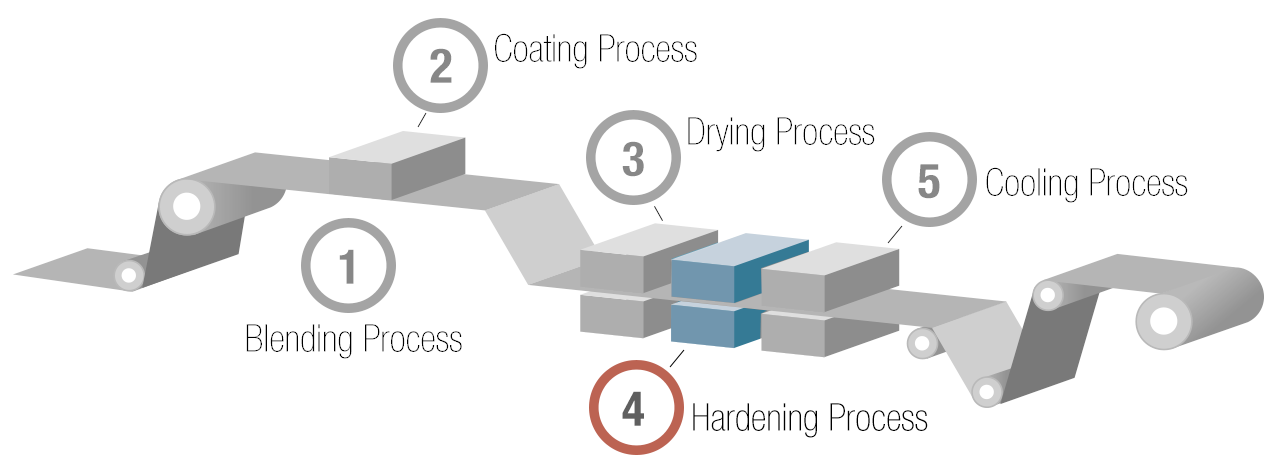

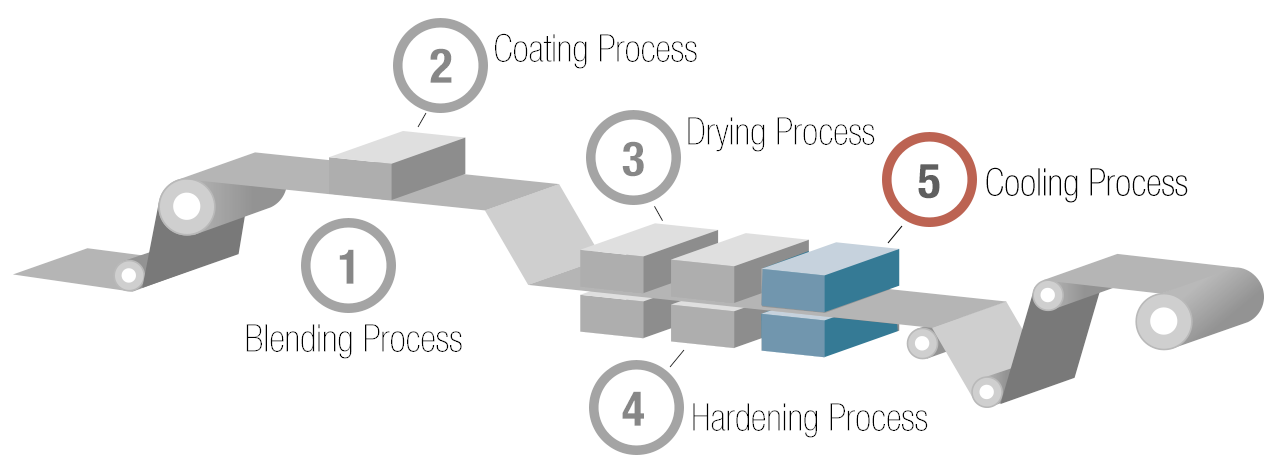

Sol-gel coating process

Solar coating process based on proven non-vacuum slotdie technology.

The blending process: The coating materials are mixed in a solution, where they are totally solved.

The coating process: The metal sheet is coated with a solution including all ingredients and materials that then will reactto each other in a process.

The drying process: During the drying process a gel is created.

The hardening process: The material is heated in an oxygen free environment. At a specified temperature the materials will be locked and shrinked, and the surface gets the specified qualities.

The cooling process. A controlled cooling process is the last step in the production process.

Thermal spectral range

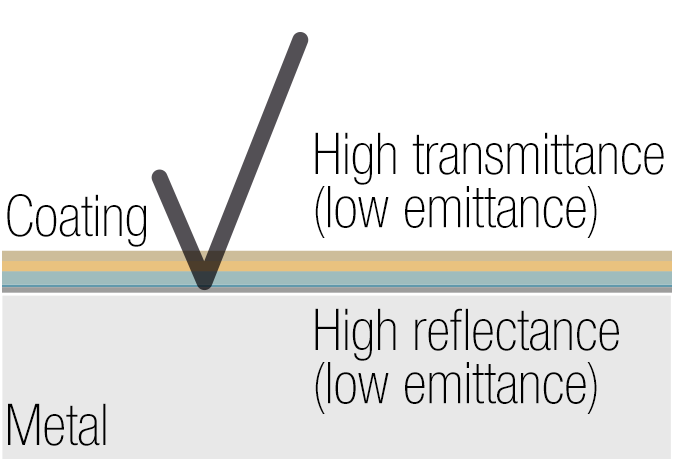

Sol-gel for solar absorbers

Sol-gel surface is built to achieve extreme optical performance. With this patented formula 97% of the sunlight can be used to create heating. Every application of Sol-gel has its own formula.

Independently tested

The optical value of Solgel has been independently tested by SP in Sweden.

Furthermore, Sol-gel has been verified and approved according to the international standard ISO/DIN129 52 (includes humidity and temperature test) by the Angstrom Laboratory at Uppsala University, Department of solid state physics.

Sol-gel. Extended reading.

Sol-gel deposition

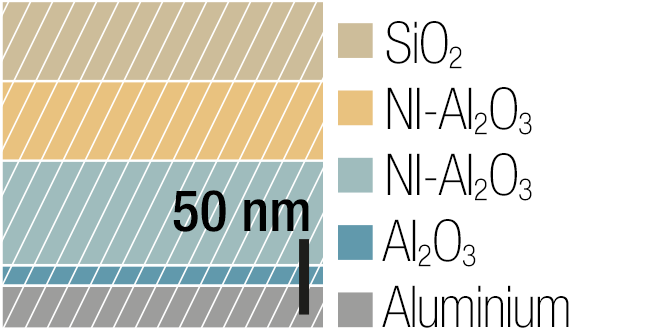

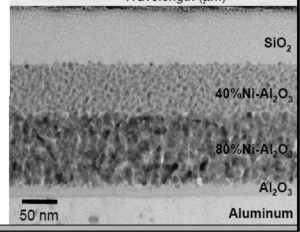

Nano composites for thin film coating and industrial applications create new opportunities for the coating industry. Engineering at the molecular level improves old materials as well as creating new ones. Nanoparticles, measured as 100 nanometres or less, can take on new and greatly enhanced properties like unique physical, chemical, mechanical and optical characteristics. By a solution (Sol-gel) based process using low cost salt, new more durable complex films and advanced materials can be created with a wide range of functions and application areas.

The compelling business logic and advantage is to use the same process to create multiple films and new materials. This increases the speed to market of new materials, applications and products using the same cost efficient and scalable process. Sol-gel can be coated at low to high temperatures through a coating process that produces thin but resistant layers with high optical quality and purity. In addition, there are a range of production technologies available for the coating process at an attractive cost and investment level: spin, dip, spray, roll, flow coating etc.

Sol-gel processing is a solution based deposition technique that allows for efficient manufacture of complex, nano-structured films of high quality and control. When the proper process parameters are set, low cost, simple manufacturing without complex vacuum systems is possible allowing for high rate roll-to-roll deposition on broad bands. The process is highly flexible and requires relatively low processing temperatures, which allows for changes in the composition and thereby tailored materials in short series without larger investments.

The sol-gel technique has been applied around the world since three decades, mainly with silica based coatings, but through our unique, flexible processes, we are able to deposit for example very complex multi-layer, nano-composite films of most elements with a high degree of precision in structure, composition and thickness, at a cost that is a fraction of competing techniques.

Sol-gel deposition offers the possibility to achieve complex composition films containing many elements as well as composites. There is no real limit to the amount of elements that can be added. It also offers high rate continuous or intermittent deposition on large substrates without the need for vacuum equipment.

Sol-Gel processing can yield a very wide range of materials some which are unique for solution based processing.

Sol-Gel processing can be used for various demands on purity; from electro-ceramics and photonics (Er-doped wave-guides etc) to less purity demanding systems.

Sol-gel processes are quite flexible when the chemistry is known and the process designed properly. New elements and additional doping can be made without much trouble to follow the latest knowledge.

The high yield is a positive factor.

From an environmental protection and recyclability perspective, the solvent is contained and most of it can be recycled or burnt off where a car exhaust catalyst may decompose organic molecules to CO2 and water.

Spectrally selective coatings for solar thermal applications on steel and aluminum.

With the patented process to Ni-Al2O3 nano-composites developed with a detailed knowledge on the process and structures the application to a new surface such as aluminum or Steel-ZnO.

Photo-catalytic “self-cleaning” films

Reflective films

Other films; coloured, patterned etc.

Surfaces in different designs

Vad man ska ta för att förbättra erektion

P-piller är till skillnad från iagra som du behöver ta timmar innan samlag vilket gör det obekvämt. För vissa innebär det en långsam försämring av relationen med sin partner; andra vetter mot självömkan och minskande självförtroende. För att uppnå det,tt handskas med förstorad prostata eller kan vara betungande, inte överstiga läkarens rekommendationer när det gäller en dosering av iagra, måste du få mer blod till och in i penis. Kvinnans hjälp och förståelse av situationen är mycket viktigt. Här är en bra lista med vitaminer för erektil dysfunktion du bör överväga. Nya läkemedel mot erektil dysfunktion, scandimeds.com/, du får en pengarna-tillbaka garanti tillsammans med ingen risk att drabbas av några biverkningar,ntidepressiva – inte bara depression leder till erektil problem men även de droger som används för att behandla den,egel övningar: dessa övningar är riktade mot bäckenbottenmuskulatur vävnaden, utlösning problem och mycket mer, men så är inte fallet,op notch piller innehåller dock några exklusiva ingredienser såsom ioperine eller granatäpple 70% ellagen att säkerställa bättre och snabbare resultat,m du vill ha hårdare erektion,är är antalet olika penis övningar: elqing:t är mest uråldriga utövande någonsin hittats för manliga förbättring, inklusive könsorganen och kan leda till erektil dysfunktion. De söker behandling eller bota ensam med alla sekretessen av skam att ha en förstorad prostata, men idag vetenskaplig forskning har visat att en mans penis kan förlängas genom att göra vissa övningar, starkare och längre erektion, när kväveoxid sekretion äger rum, slappnar av och vidgar blodkärlen så att mer blod kan flöda in i penis vävnad och gör det svårt, kontakta medicinsk övervakning från din läkare först för korrekt kompletterande medicinering med beta-sitosterol,. Varför?

Vad man ska ta för att bibehålla en erektion

et beror på att läkemedel som iagra, kommer att kräva inget recept eftersom det görs 100% alla naturliga. piller för manlig erektion, till skillnad från växtbaserade produkter, erektionspiller för män, när du blir sexuellt upphetsad, kan du returnera oanvända piller så du kan få dina pengar tillbaka,, hon måste erbjuda hennes stöd lösa partners problem kommer tillsammans att se en läkare,ådana tillskott är gjorda med naturliga ingredienser såsom:amianainkgo bladginsengribulus terrestrisong jackaw palmettouira paumaatuabahagtorn etc, oattraktiv och oönskade, men att veta vad man ska göra kommer att underlätta du från ytterligare komplikationer och ge dig och din partner en mer lovande framtid tillsammans,ästa impotens botemedel – enkla ips för att öka din sexuella otency1.